When it comes to manufacturing, there are two main types of processes: 3D fabrication and 3D construction. But what is the difference between the two? And which is more common in today’s industry? Read on to find out!

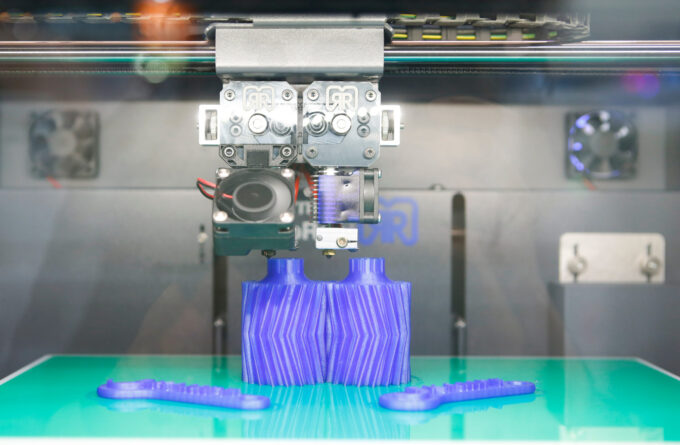

What is 3D Fabrication?

Source:makerbot.com

3D fabrication is a process of creating physical objects from digital models. It is a type of manufacturing that uses three dimensions to create an object from a digital model. 3D printing is the most common technique used for 3D fabrication. It creates an object by depositing layers of material one on top of the other. The final product is often less than 1/10th of the original model size.

There are several types of 3D printing technologies: stereolithography, micro-machining, and selective laser sintering. Each has its own advantages and disadvantages.

– Stereolithography is the most common type of 3D printing. It uses a stereoscopic camera to create a model from a series of photographs. The final product is a three-dimensional object that is made up of thousands of tiny layers.

– Micro-machining is another type of 3D printing. It uses small machines to create detailed parts. The machines use a variety of techniques, including milling and cutting.

– Selective laser sintering is the latest type of 3D printing technology. It uses lasers to fuse together small pieces of plastic to create an object.

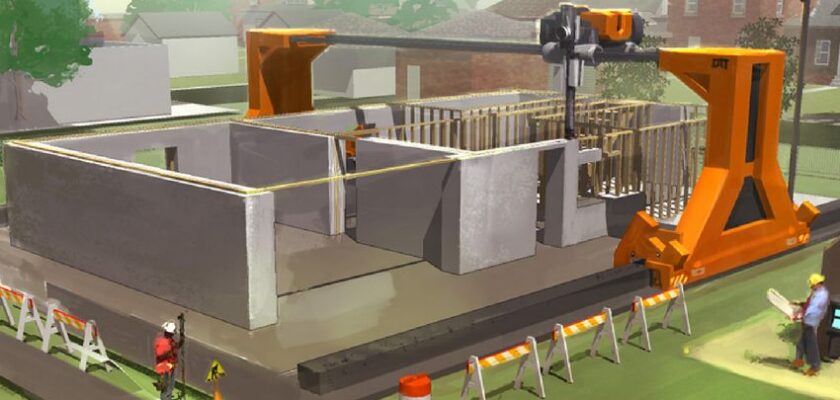

What is 3D Construction?

Source:youtube.com

3D construction is a process of creating physical products from three-dimensional data. This is different from traditional two-dimensional construction, which simply creates flat panels or solid objects from two dimensions of surface. With 3D construction, designers can create products that are more realistic and accurate than ever before. This is thanks to the use of advanced 3D printing technology and computer-aided design (CAD) software.

It has many advantages over traditional construction methods. For instance, it can reduce the amount of waste that is produced during construction. It can also improve the accuracy and quality of products.

3D construction is becoming more popular as manufacturers seek new ways to reduce costs and improve product quality. It is likely that 3D construction will become an even more important part of the construction industry in the future.

The Pros and Cons of 3D Fabrication and 3D Construction

3D fabrication and 3D construction are two popular methods of creating products from digital models. 3D fabrication services include creating products by printing them out from a digital model. 3D construction is similar to 3D fabrication, but it uses software to create the product instead of printing it out.

Pros of 3D Fabrication:

1) 3D fabrication is cheaper than 3D construction.

2) It can create more detailed products.

3) 3D fabrication can create products that are lighter and smaller than products created with 3D construction.

4) It can be more accurate than 3D construction.

5) More complex objects can be created with 3D fabrication.

6) It is easier to change the design of a product created with 3D fabrication than with 3D construction.

7) There is less chance of mistakes when creating products with 3D fabrication.

8) It is possible to create products in different colors and styles with 3D fabrication than with 3D construction.

9) It is possible to create products that are interactive.

Cons of 3D Fabrication:

1) It is harder to create products that are interactive than with 3D construction.

2) It is more difficult to change the design of a product created with 3D fabrication.

3) It is more difficult to create products in different colors and styles than with 3D construction.

Main Difference Between 3D Fabrication and 3D Construction

Source:onekeyresources.milwaukeetool.com

3D fabrication and 3D construction are two types of manufacturing that are gaining more and more popularity among manufacturers. However, there is a big difference between the two. Here is a quick overview of the two processes:

– 3D Fabrication: In 3D fabrication, a 3D model is created from multiple 2D slices. This process allows for very accurate and detailed products to be produced. 3D fabrication is used for products that have intricate details and require high levels of precision.

– 3D Construction: In 3D construction, a 3D model is created from multiple layers of data. This process allows for products to be produced quickly and without any errors. 3D construction is used for products that do not require intricate details or high levels of precision, but instead need to be relatively simple in design.

Benefits of Using 3D Fabrication Over 3D Construction

- Less time and costs: With 3D fabrication, you can create a three-dimensional object faster and at lower costs than with 3D construction.

- Greater flexibility and creativity: With 3D fabrication, you can create objects that are more flexible and creative than with 3D construction.

- Better quality: With 3D fabrication, you can get better quality results than with 3D construction.

- More accurate results: With 3D fabrication, you can get closer to the final desired result than with 3D construction.

- More realistic results: With 3D fabrication, you can get more realistic results than with 3D construction.

To Wrap It Up

Source:blog.drupa.com

If you’re reading this, it’s likely that you’re interested in learning about the different types of 3D printing technologies available and what each one can offer. There is a lot of confusion circulating between the terms “3D fabrication” and “3D construction.” In this article, we will try to clear up the differences between these two methods and help you decide which one is right for your project. We will cover everything from what 3D fabrication is, to its benefits, to different types of3D fabrication. Hopefully this will help you make an informed decision about whether or not 3D construction is the right approach for your next project. By the end of this article, you’ll have a better understanding of both terms and which type of 3D printing technology is best suited for your specific needs.