Graphite electrodes are a critical component of many industrial processes and are used in a variety of applications. But what are they and how do they work? In this blog post, we will explore the basics of graphite electrodes, including their uses, advantages. We will also discuss the importance of graphite blocks in industrial processes. By the end of this post, you should have a better understanding of graphite electrodes and their applications.

What Are Graphite Electrodes?

Source: linkedin.com

When it comes to technology, nothing is ever complete. That’s why we’re always looking for new and innovative ways to prevent melting and increase the lifespan of our devices. That’s where graphite electrodes come in. These small, yet powerful, electrodes are made from a type of carbon known as graphite.

They work in a variety of ways, but their most important function is preventing device melting. Devices that use graphite electrodes – such as cell phones and laptops – are less likely to melt in hot climates or when they’re subjected to extreme temperatures. This makes them a great choice for devices that are used in warm environments, such as cars or planes.

Graphite electrodes also come in a variety of shapes and sizes, which makes them suitable for a range of devices. They’re also easy to store and transport, making them ideal for use in manufacturing or industrial settings. In addition, because they don’t corrode like other electrode materials do, they have a long lifespan – up to 10 times longer than copper electrodes!

When choosing an electrode material, it’s important to consider both the advantages and disadvantages of each option. Graphite electrodes offer many benefits over copper electrodes (such as improved longevity), while copper has some unique advantages over other materials (like being able to conduct electricity better). Ultimately, the best option for your device depends on the specific requirements that you’re looking for. That said, using them will almost always result in longer device lifespans overall!

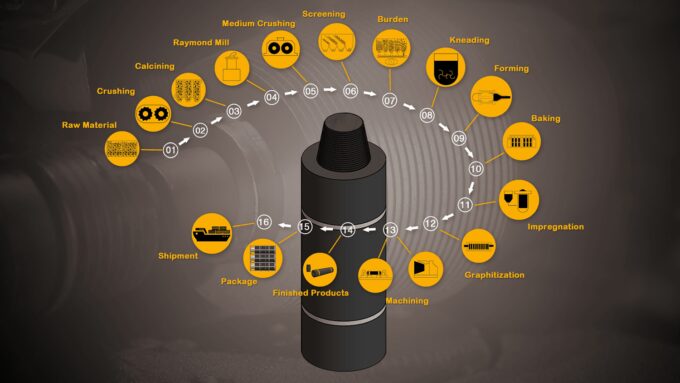

The Process Of Making Graphite Electrodes And Their Uses

Source: graptek.com

Have you ever wondered what makes graphite electrodes so special? Well, underneath the dusty surface is a material that has many incredible uses.

– First, let’s define what a graphite electrode is and its purpose. A graphite electrode is made from a mixture of carbon and other elements, such as sulfur, that are heated until the carbon particles combine to form graphene. The graphene is then isolated and used in various industrial applications. Some common uses for graphite electrodes include smelting and metal refining.

– Now that we know what a graphite electrode is and what it’s used for, let’s take a look at how they are made. They are usually made from two types of materials: natural or synthetic materials. Natural materials include coal, while synthetic materials include asphalt or plastic fibers. The type of material used will affect the overall quality of the electrode. For example, asphalt-based materials will be cheaper but less durable than natural materials like coal.

– Overall, graphite electrodes have many advantages over other types of electrodes when it comes to their performance in industrial applications. They are lightweight which makes them easy to transport and handle, they’re resistant to corrosion which means they can last longer than other types of electrodes in harsh conditions, and they’re also non-toxic which makes them safe to use in proximity to people or animals.

– In addition to their industrial applications, they have many potential environmental benefits when it comes to their production process too! For example, using recycled materials instead of new resources means that there are fewer negative impacts on the environment overall – something that should be taken into account when thinking about using new technologies like this one!

Graphite Block Applications

Source: machinedgraphite.com

When it comes to industrial processes, nothing is more important than the electrical current that flows through it. That’s where graphite block applications come into play. These conductive materials are used in arc furnaces to provide an uninterrupted flow of electricity. This is especially important in industries such as steel production and automotive manufacturing, which need a reliable source of power to function.

– In addition, graphite blocks offer superior electrical properties when compared to other materials such as metal or plastic. This makes them a great choice for applications that require high levels of current or voltage, such as welding and cutting.

– Another advantage of using graphite blocks is their flexibility – they can be custom-made to specific requirements which can prove useful for many purposes beyond simply providing electrical current. For example, they can be used as decorative pieces in architecture or art. They also offer excellent thermal conductivity, making them an ideal choice for applications that involve high temperatures – like car manufacturing or steel production.

All things considered, they are an excellent choice for industrial processes that require reliable electrical current and superior thermal performance. Their versatility makes them perfect for a wide range of uses across many industries – so don’t hesitate to give them a try!

Understanding Graphite Electrodes And Their Benefits

There are a number of benefits that can be obtained from using graphite electrodes in the workplace. These electrical conductors are composed of carbon, graphite and other minerals, which makes them an ideal solution for a variety of industries. Some of the benefits that you can expect to see with them include:

· High levels of thermal and electrical conductivity – This makes them ideal for welding applications where high levels of heat or electricity need to be transmitted quickly and efficiently.

· Arc resistance – Graphite electrodes have a high arc resistance, which means that they are resistant to fire and melted metal during welding. This makes them a great choice for welders who require high levels of safety and productivity.

· Cost efficiency – They provide increased cost efficiency due to their high level of thermal and electrical conductivity. This means that you will be able to reduce costs by using fewer materials overall, which in turn will lead to reduced production costs.

They can also be customized to meet the specific needs of different applications. This means that they can be easily adapted to meet the needs of different industries or business models.

In Conclusion

Source: saturnedm.com

In conclusion, graphite electrodes are a valuable and versatile component in many industrial processes. They offer a long lifespan, cost-efficiency, and protection against corrosion. Their high thermal and electrical conductivity also make them an ideal choice for applications requiring high heat or electricity. Additionally, graphite blocks can be customized to meet specific needs, and they are even used in art projects or architecture! Overall, graphite electrodes are an invaluable tool that can help any industry save time and money while providing reliable performance.