Unconventional particle separation treatment processes are very important in the production industry today. They enable the processing of new difficult-to-process materials with specific properties which could not be processed by conventional procedures. By separating particles without direct contact between the cutting tool and the workpiece and the introducing new types of energy, a new one has opened up perspective in terms of particle separation processing. Although there are many different unconventional processing procedures and each of them in some segments represents an improvement and improvement of processing, none can fully meet the growing demands of the product and markets. Conventional and unconventional processing procedures are actually complemented in production and do not compete with each other in all areas of application. As a result of efforts to achieve higher productivity and quality, new hybrids are being developed procedures that combine several conventional and unconventional procedures.

Science and technology, following the needs of modern man, strive every day to create the most perfect products at the lowest possible cost. Due to that, new production processes are being developed and their number is constantly increasing.

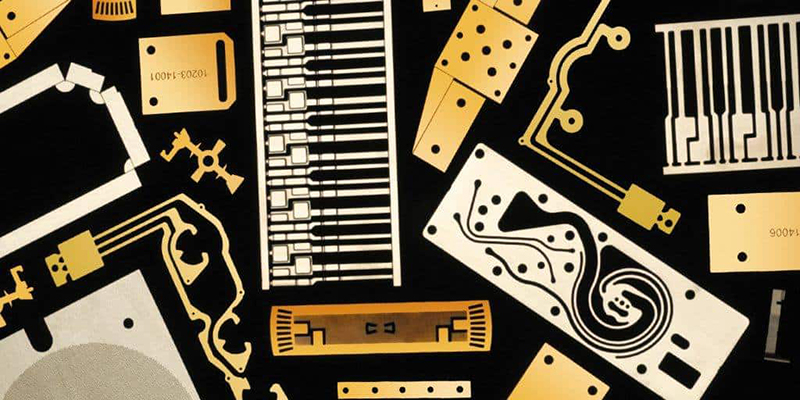

In the manufacturing industry, it is often necessary to precisely make small parts from different materials – aluminum, stainless steel etching, copper, beryllium copper, brass, phosphorus bronze, alloy 42, nickel, nickel silver, Kovar, Inconel, Invar, Molybdenum. The production that meets the criteria of all these materials is photo etching.

For photo etching, it is a technique of making small parts with the help of designing shapes in a CAD program. Today, there are machines that precisely create the desired shape based on drawings. In order to reach the final product, it is necessary to take a few steps.

Technical drawing

Source:precisionmicro.com

As we have already mentioned, it all starts with a drawing. The drawing shows the product in two-dimensional form.

Program writing

The program is written according to the technology defined in advance in the technical preparation. It can be programmed manually or by computer. A manual programming technician writes line by line according to defined machine instructions. Computer programming is programming defined program parameters in the provided software packages (software).

In principle, machining is a way of transforming a basic piece of material, such as e.g. block plastic, into a finished product (usually a prototype product) using a controlled material removal procedure. So, these machines rely on digital instructions from CAM or CAD programs. Although CAM or CAD do not run the CNC machine itself, they provide a guide for CNC design.

Control units

Each CNC machine is controlled by a program (software) and a control unit. The control unit is divided into an address – numerical unit and a machine – control unit.

Production

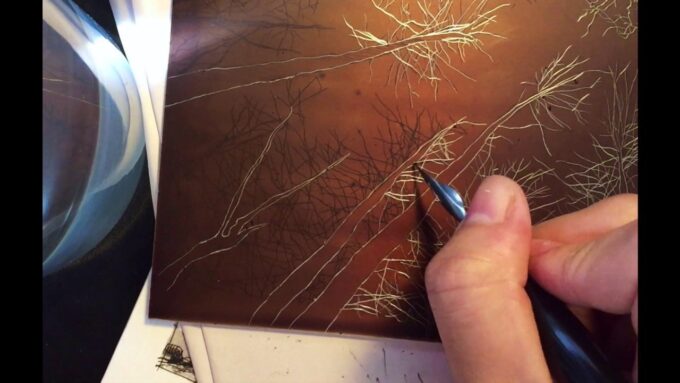

Source:londonfineartstudios.com

Now that you have given the necessary instructions for creating a specific product, photo etching can start.

The photo etching process is very similar to the chemical milling process, except that 3D parts already formed by other processes are processed by milling, and very thin materials (0.013 – 1.5 mm thick) are used for photochemical processing to obtain accurate micro shapes. It is suitable for machining very fragile elements where conventional machining could cause stresses and breakage. The products created by this process are used in electronics, aviation, telecommunications, and medicine.

What sets photo etching apart from conventional processing procedures is less time consuming, does not cause deformations and distortions, accuracy and speed are much faster than other methods, and photo samples can be saved and repeated production if necessary. It is used in serial production in the processing of electrically conductive materials that are difficult to process and in the processing of geometrically complex shapes, e.g. molds, forgings, tools, turbine parts, and reactors.

The most important machining operations are drilling small and large holes, making turbine blades, machining external surfaces, electrochemical “drawing”, machining profile surfaces, removing sharp edges, and so on. ECM-processing can practically be used to perform many operations that shape various surfaces, similarly to conventional processing of turning, drilling, milling (especially profile), planing, drawing, threading, making gears, etc. In all these operations, it is important that the shape of the electrode tool and the movements during machining are mutually harmonized in order to obtain the desired shape of the surface.

What we would definitely single out as an advantage in photo etching is high productivity and high-quality workmanship, dimensional accuracy of 0.02-0.2 mm, and no tool wear. On the other hand, there are certain disadvantages such as expensive equipment, high electricity consumption, and it is possible to build exclusively on materials that produce electricity.

The development of photo etching machines has greatly facilitated industrial production. Modernization of factories with these machines gains efficiency and greater profitability for the company and manufacturers. Like these types of machines are beginning to be used in almost all branches of industry that require mass serial production lasting 24 hours a day, 7 days a week without a break.

Unconventional particle separation treatment processes are very important in the industry today production. They enable the processing of new difficult-to-process materials with specific properties which could not be processed by conventional procedures. By separating particles without direct contact between the cutting tool and the workpiece and the introducing new types of energy, a new one has opened up perspective in terms of particle separation processing. Although there are many different unconventional processing procedures and each of them in some segments represents an improvement and improvement of processing, none can fully meet the growing demands of the product and markets.

Final thoughts

Source:masteretching.com

Photo etching is able to independently machine parts without limiting factors, whether it is parts of very small dimensions, small details, or tolerance required by the technical specification of the part. Microprocessing is one of the requirements for modern production and is a challenge to apply because it can not be understood according to the same principles as macro processing. Therefore, it also presents some of the obstacles and physical phenomena that should be studied in more detail in order to successfully overcome them.