You probably thought that there will never be a moment when you’ll be interested in linear slides. But, here we are. You might also hear of them under the name of linear bearings. Whichever it is you should know from the beginning the importance of this device when it comes to creating any type of automated or machining setup. Their main function is to keep the machine operating smoothly, in a straight line, and above all else with precision. Once you start getting known with linear slides you’ll learn that there are different types out there. What remains the same is that they’re compromised from a base and a saddle, the two essential parts.

First, let’s talk about the saddle or as some would call it a carriage. Both terms are acceptable. The same as with the horse riding saddle is there for support. In this case, it’s not there for the raider but for any sort of payload which will be moved by the linear slide. When it comes to the carriage the setup doesn’t always have to be the same. Sometimes the top of the saddle is in charge of holding the moving part of the system. In other instances, it can be tied to the bottom or even to the sides.

The main counterpart to the carriage is the base. With a standard configuration, the carriage is what is tied to the rotating parts of the linear slide. At the same time, the base, as its name suggests, is the stationary part of the equation. But, as we already said, some configurations are set up differently.

Now that you know the two essential parts of every linear slide and linear actuator you need to know that their primary function is to limit the range of motions of these machines. In the majority of cases, they need to keep a straight line. Furthermore, they are in charge of reducing any friction that can happen within a machine and its moving parts. What’s important once you install this device is that all metal-to-metal friction is eliminated, which aids in the smoother operation of any given machine.

Types of Linear Slides

Source: pbclinear.com

To get an even better grasp of these mechanisms you need to learn what types there are. So, the next time when you’re shopping for linear slides by Tuli you know precisely what you need. Below we are going to list a few options you have in this department. You’ll be surprised at the sheer amount there is available. Let’s start with the basic ones first

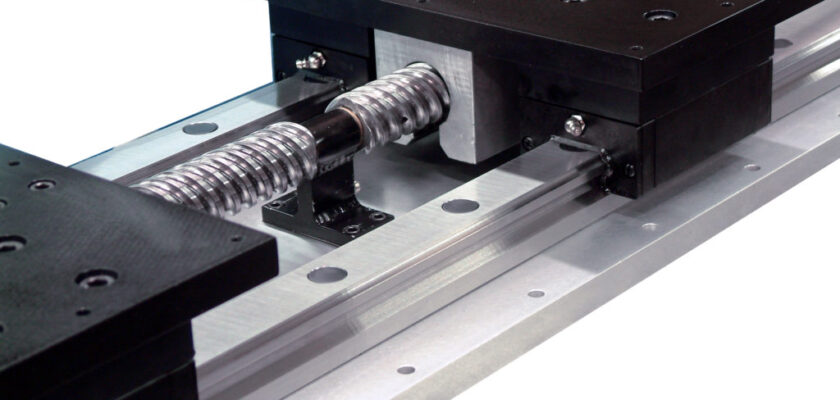

Linear & Ball Slides

These two are the first kind we’re going to cover. As you can already tell the linear ones are intended for straight motion only. They’re the ones providing the air cushion to different parts of a machine and making it possible to create a straight motion with no friction. Here, you’ll also encounter the ball slide. The system is similar to the linear one with the difference being that the base.

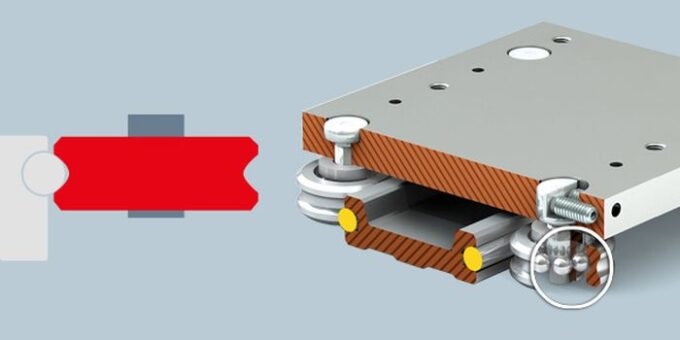

Crossed Roller Slide

Source: thkstore.com

These slides are the kings of accurate positioning. The name comes from the position these slides take upon installation. We’re talking about a set of rollers that are v-shaped, and installed under a 90-degree angle. Due to this setup, they are able to take on heavy loads. The best part is that they do not take up a lot of space once you install them.

Dovetail And Hardened Way Slides

These are unique slides. What makes them unique is that they are very resistant to shocks and vibrations. Compared to the options from above they are much better at it. This is made possible for them because they rely on lower profiles. With higher stiffness there comes the ability to take on heavier loads. In this paragraph, we also need to mention the hardened way of slides. If the name doesn’t ring a bell they are also known as box way slides. We put them in the same line as they are quite similar. What makes them nearly identical is that with them there is direct contact between the carriage and the base.

Linear Motion Guide Slides

Source:facebook.com

As the name suggests we are talking about slides that have a guide rail. It is located right next to the saddle unit. Some people also know them under the name of square rail linear bearings. What makes them unique is almost ideal precision with the ability to carry a heavy load. In addition, they are also praised for exceptional stiffness which in combination with everything above makes them a truly reliable choice.

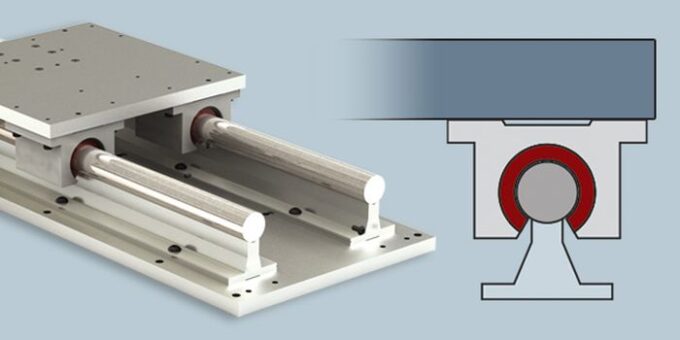

Linear Ball Bearing Slides

Here we have another mechanism based on using the balls to create the needed traction within any machine. This mechanism relies on the saddle mounting whereas shafts are also linear and quite hardened. These are used in situations where there might be misalignment which could create torsion which is then accommodated by linear ball-bearing slides.

Linear Needle Roller Slides

With this setup, which is also called M/V, you have needle roller rows contained by a V-shaped retainer. The name comes from the way these needle rollers are positioned within a machine. One roller is set up along the M rail while the other one is positioned along the V one. Hence the name. Due to this setup, it can carry heavy loads. But, even with heavy loads mounted it doesn’t lose any of its accuracies. The one downside might be the additional stiffness.

Bottom Line

Source:pinterest.com

As you can see, linear slides are no simple mechanism. They come in various shapes and sizes, and each of them has a unique appliance. Depending on how you intend to use it, and how your setup looks like you’ll be able to determine the type you’ll need. They are divided by the traction they create or avoid creating, the payload they can take on, and the consequential stiffness. While in the beginning, they can confuse a first-time user, the more you look into them, linear slides get much easier to understand and make use of them.