Do you like when you get a gift that is meant just for you? The gift itself doesn’t have to be too expensive – but if your name is on it, you’ll admit that its value is far greater. Fortunately, with the development of laser technology, such gifts are no longer a rarity. Today, with the help of laser engraving techniques, we can personalize almost everything. Still, have you ever wondered is laser engraving technology environmentally friendly? The answer might surprise you.

Laser Engraving And Its Wide Application

Source:sculpteo.com

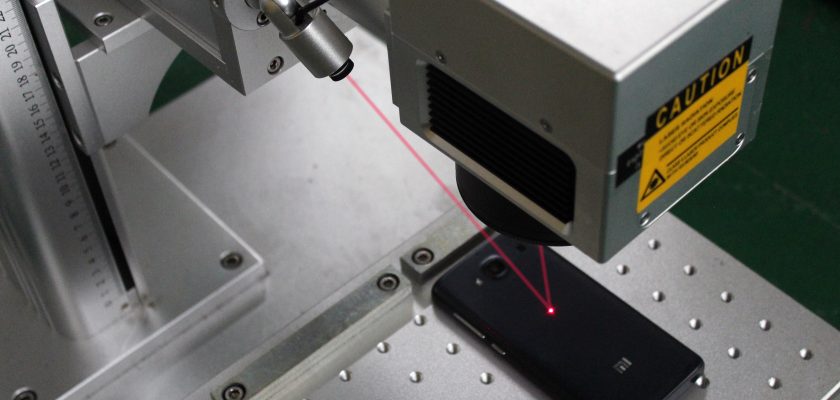

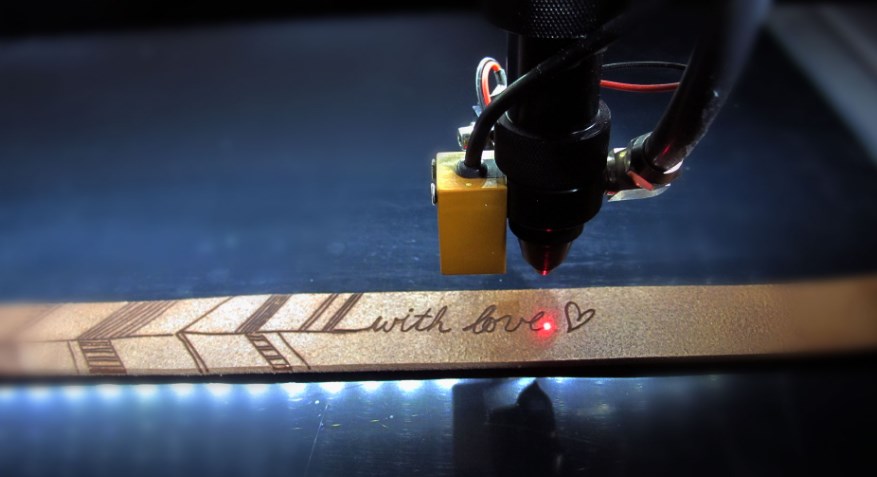

Laser engraving is modern technology – but it has also been in use for a long time. However, as with any technology, many things are changing. Nowadays, systems are being modernized, and thus the range of engraving products is expanding. Laser engraving is also a very popular method of personalizing gifts today. In the case of company requirements, these are most often pendants, ballpoint pens – or notebooks with a leather binding, on which the name or logo of the company is imprinted. However, in recent years, engraved personalized gifts that can be made from a variety of materials are in trend.

Source:americanplasticusa.com

Laser Engraving For Gift Personalization

We mention this for the simple reason that it has become almost the most popular branch in the field of laser engraving today. Laser gift engraving is done on all materials without exception. You can work on the gift item itself or its packaging – that is, on the packaging. Of course, depending on the material, the type of laser engraving machine also depends. For example, jewelry engraving is also a very popular method of personalizing gifts today – and most often engraved symbols or texts of dedication to loved ones for whom the engraved jewelry is intended. Laser engraving can be done on jewelry and precious metals, gold, silver, platinum. A jewelry laser engraving machine is used for such a procedure – and you can visit here, and see what other types of engraving machines are in use. Existing differences in materials are irrelevant to laser engraving, but still, if you are a beginner in this job – you should know what to start with.

Are There Dangers Of Laser Machines?

Source:wileymetal.com

Laser machines are most often operated with the help of computers and special computer programs. This is how the operation and proper functioning of the laser machine are coordinated. The whole engraving process depends on that coordination and its validity. When the issue of the safety of using laser engraving machines is mentioned, it is somehow always related to our attitude towards the environment. We must mention that laser machines work on the principle of radiation – but following standards and safety measures, every risk, even the one around the environment, is reduced to the maximum possible minimum.

What Is The Greatest Danger To The Environment When You Use Laser Machines?

As with all other devices or machines – here, the greatest risk is the human factor. With improper handling, dangers are always possible. But let’s be honest – it’s the same when you use a gas or electric stove. Therefore, in this sense, it is sufficient to take into account and respect the international standards of use – as well as the characteristics of these machines. This way, you will reduce every risk to a minimum – even those concerning the environment. Certainly, the technical correctness of the machine is crucial – because, with partially correct machines, it is possible to cancel functions, including those related to safety. This is primarily the reason why experts in this field always advise buying new and not used machines. Even though used laser machines are significantly cheaper – in some cases they can cost you dearly if a malfunction occurs.

Although you will probably say that the new laser engraving machine is expensive – be sure that such a move will return your investment very quickly. Depending on the type of machine – the ROI factor can be reached in a short time.

International Standards And Technical Characteristics Ensure Safety

The fact is that laser radiation interacts with different materials – that is the essence of this technology. Therefore, it is clear that the uncontrolled operation of these machines poses a danger to people and resources in the environment. On the other hand, the operation of lasers is monitored by high voltage subsystems – as well as those for providing and distributing active or auxiliary gases, etc. That is why the general and special protection measures, which are available to every user of the laser, should be strictly adhered to – because in most cases they are an integral part of the documentation that the manufacturers supply with the device. However, as we have already mentioned – failures and improper handling are always possible with a certain degree of danger. To reduce the risk to a minimum – international standards define the technical characteristics and classes of lasers.

Learning About The Impact Of Light We Will Increase The Safety Of The Environment

In today’s conditions, we can be directly or indirectly exposed to laser radiation. However, with the advent of laser machines as light sources, things have changed significantly. What the overall effects on humans and the environment will be – depends on the incident energy and the wavelength of the light. It also depends on whether it is a laser pulse or a continuous beam. The amount of energy released can be so great – as to damage the tissues of humans, animals, and plants. Moreover, in the case of the human eye – the damage can be irreversible. The comprehensiveness of laser applications has led to the need to study the biological effects of light – and to find new techniques for the safe use of laser devices. So far, from this technology, we have more benefits than harms.

Source:2ech.com

The Bottom Line

We hope that we have been able to explain laser engraving technology – and its impact on humans and the environment. Regardless of some of the risk factors, we must not overlook the fact that the laser as such is widely used – not only in manufacturing but also in medicine, telecommunications, materials processing, and many other industries.